The second shot shows the office of the TOM (Technical Operations Manager) taking shape and, on the extreme left, the second of the two Despatch Cubicles. These cubicles are discussed on the "Sources" page.

A lot had changed by the time the next picture (left) was taken. The Control and Monitor Positions (C&Ms) would soon be positioned in the foreground, the ATOM's desk would be next to the distant pillar on the right. Behind that pillar is the door to the first Despatch Cubicle.

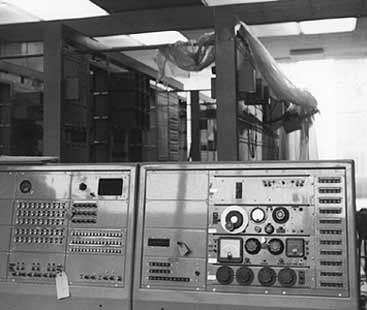

right: The equipment is now being installed. The pillar on the left is the same one that's on the left in the shot above, but we're looking from the other side of it. The end of a C&M is on the extreme left, the left end of what would colloquially be known as the "front bench" is towards the right and some bays can be seen in the background. Everything is protected by plastic sheets.

left: The Control and Monitor positions. Junior Control Room staff would spend many hours sitting in front of these desks....!

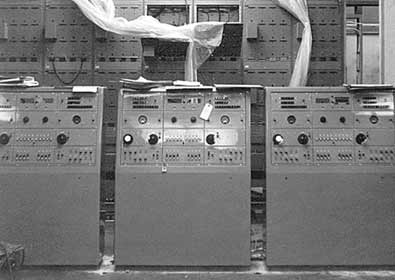

The plastic sheets are coming off! These two shots show the area which handled outside broadcasts. Barry Taylor explains.....

The OB position dealt with all UK outside broadcasts. Whereas some organisations rent equalised lines from their PTT, the BBC did its own equalisation rather than renting lines from the GPO 'ready to go'.

Work for the day's commitments started on the night shift when the TO on duty would check DC test all the lines booked for the next 24 hours. This depended on lines at the OB point having been looped correctly; A-legs of the music and control lines being joined and likewise the B-legs. At OB points used frequently by non-technical staff such as sports reporters with a COOBE (Commentator Operated Outside Broadcast Equipment) this looping was effected automatically when the equipment was disconnected. The tests involved checking insulation to earth of the A and B legs, the insulation of the A to B legs, a check that the resistance of each leg was near identical and the loop resistance of the lines. At one time these tests were done with a megger but this had been superseded by a tester that simply needed the lines plugged in, the measurement selected and the reading on the meter noted. If any readings were suspect, 10 seconds or so of ringing voltage (70 volts at 17Hz) usually cured most faults.

On the day and evening shifts a lot of the work involved booking rented circuits on and off with the GPO both for radio and the adjacent TV sound position. There were also OBs to be set up. The OB chain started with the GPO local end. This was plugged into a rep coil (repeating coil - a 1:1 precision transformer to ensure common mode rejection of any noise on the line), then to a passive equaliser or equalisers. The equalisers were all 600 ohms in and out so that they could be connected in tandem if required. After the equaliser came a variable attenuator to standardise the level at -50dB after which it was amplified to zero level by a GPA/4A, which was adjustable in ½dB steps. An informal AC test was made if the OB was manned and finally a listening test to ensure that the perceived noise on the line was as unobtrusive as the measurement suggested it would be.

The equalisation settings were produced by lines department and provided on file cards not only for permanently rented OB lines (such the Royal Albert Hall) but also long distance 'occasional programme' OP circuits that may have only been rented infrequently. So if the GPO offered say Birmingham OP3 to replace a faulty SB then the equalisation for that line was invariably available.

At one time routine AC testing was a part of the job on OBs (frequency response, distortion and noise measurements) but this chore was eliminated by an automated sweep generator and pen chart recorders and a rationalised testing schedule.